Modernizing Manufacturing: Using Computer Vision for Real-Time Quality Control

Key Takeaways

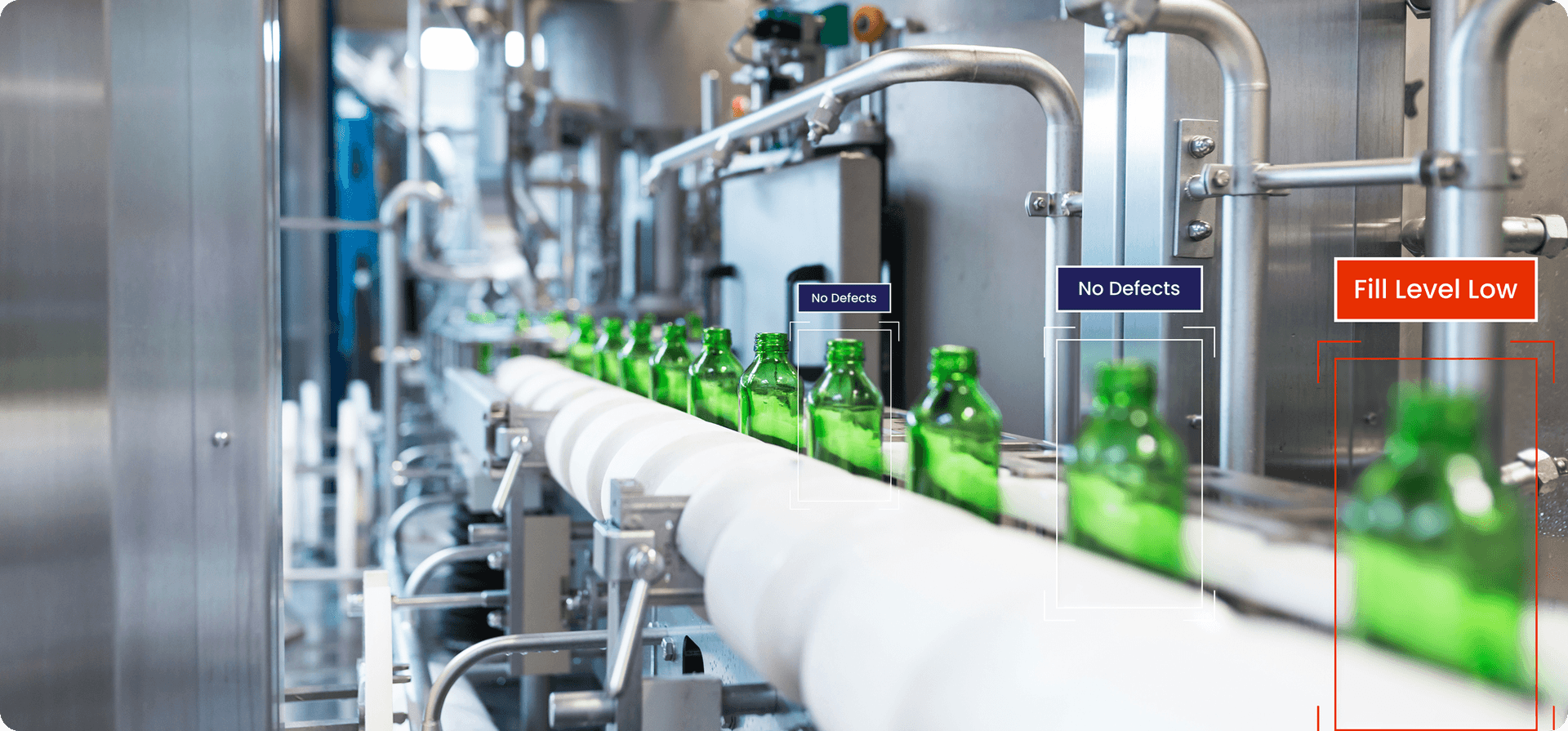

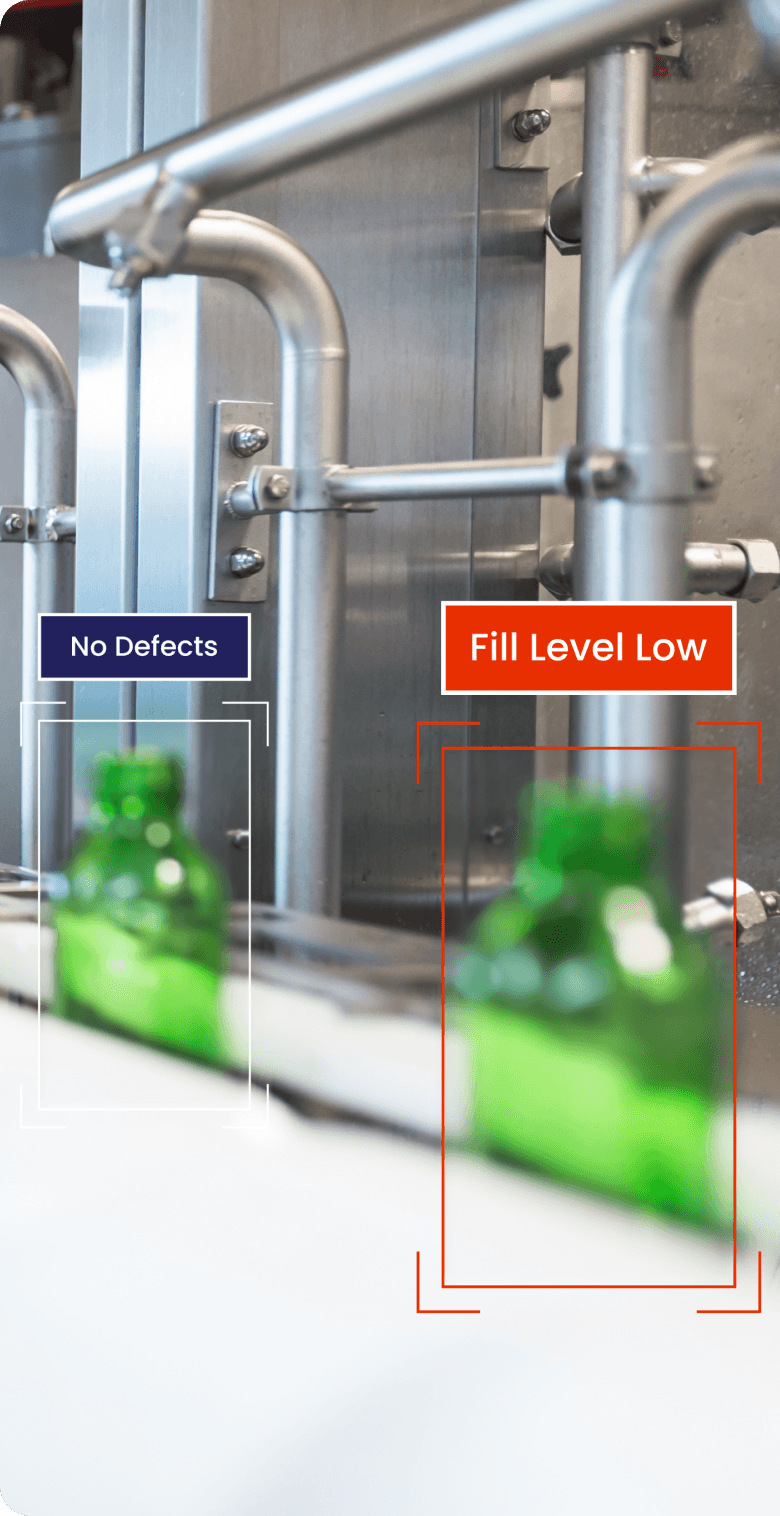

- Computer vision achieves 98–99% accuracy for trained defects, enabling manufacturers to slash scrap and waste by up to 20–30%.

- The technology identifies micro-defects invisible to the naked eye, ensuring total product integrity.

- Quality control shifts from a "cost center" to a profit driver by leveraging continuous, data-driven process improvements.

Why Is Manual Quality Inspection No Longer Enough for High-Speed Production?

Modern production lines operate at speeds that human inspectors simply cannot match. When your line produces 500 units per minute, expecting manual inspectors to catch every defect becomes unrealistic and financially unsustainable.

The Fatigue Factor creates a fundamental problem. Research shows fatigue causes inspectors to miss 20-30% of defects due to reduced focus and visual acuity. An inspector who catches 95% of defects in the first hour might only catch 70% by hour three. When you're running three eight-hour shifts, that fatigue compounds across your entire quality control team. The result? Defective products slip through to customers, creating warranty claims, returns, and damaged reputation.

But fatigue isn't the only issue. Human inspectors struggle with consistency. What one person flags as defective, another might approve. This variability makes it nearly impossible to maintain uniform quality standards across shifts, production lines, or facilities.

The cost of late detection multiplies exponentially as defects move downstream. Finding a misaligned component at the assembly station costs you the component and a few seconds of production time. Finding that same defect after final assembly means scrapping or reworking an entire finished product—materials, labor, overhead, and all. Industry data shows early defect detection costs 10x less than end-of-line fixes.

Manufacturers typically reduce scrap 20-30% by catching defects early; one case cut monthly scrap from 180,000 to 22,000 units.

Manual inspection also creates bottlenecks. As production speeds increase, you need more inspectors to maintain coverage. This doesn't scale efficiently. You're paying for more labor, more training, more supervision, and still accepting higher error rates.

How Does Real-Time Computer Vision Actually Work On The Factory Floor?

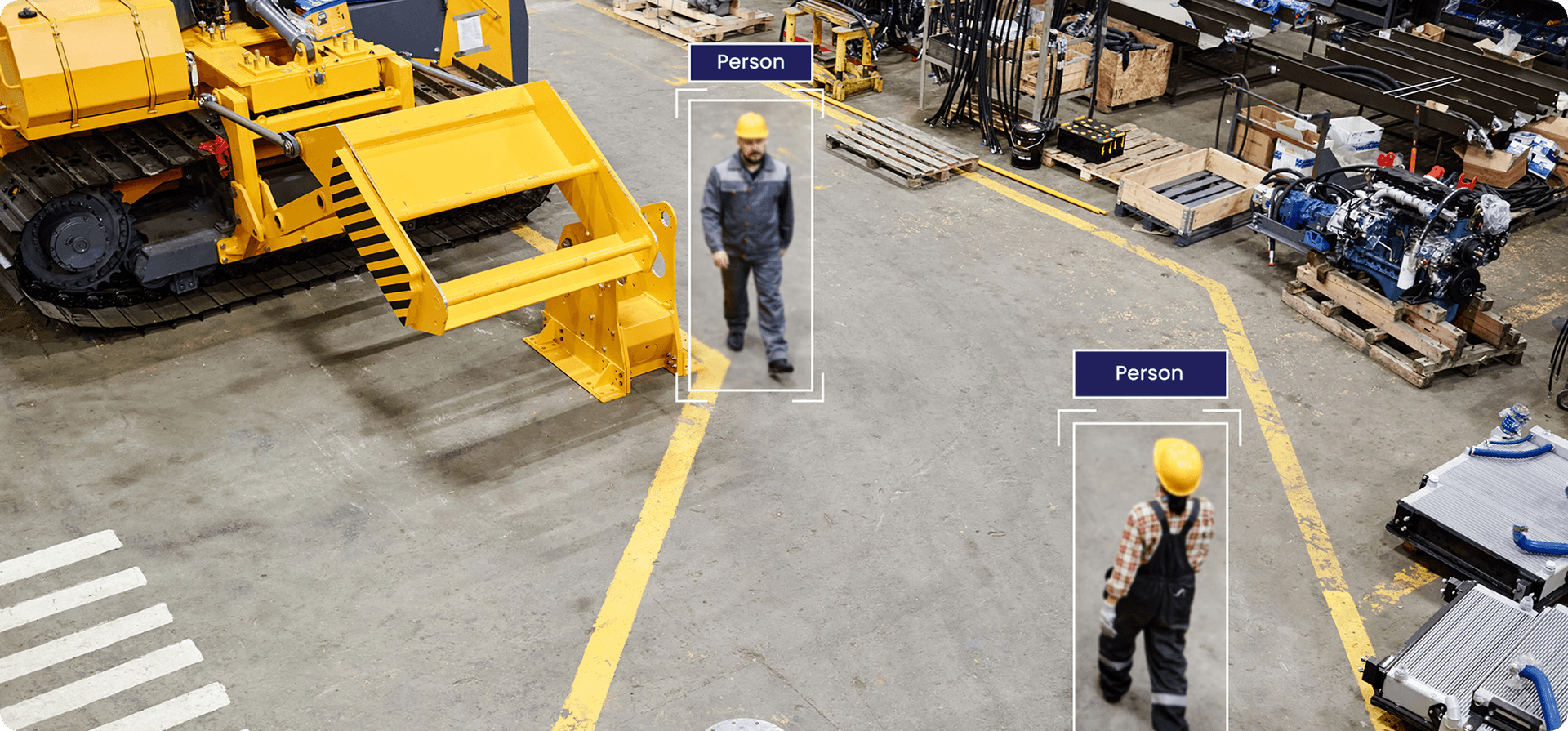

Computer vision quality control systems combine hardware and software to inspect products faster and more accurately than human eyes. Understanding this technology helps manufacturers make informed implementation decisions.

The tech stack includes three core components. High-speed industrial cameras capture images at rates matching your production speed—from 60 frames per second to over 1,000 for ultra-fast lines. These aren't standard cameras; they use specialized sensors optimized for factory lighting conditions and can capture details measured in micrometers.

Edge computing devices process images immediately at the production line. This eliminates the latency of sending data to cloud servers, enabling real-time decisions. A defect detected by the camera triggers an immediate response—rejecting the part, stopping the line, or alerting operators—within milliseconds.

Deep learning models power the actual inspection. Convolutional Neural Networks (CNNs) and Vision Transformers analyze images to identify defects. These AI models learn what "good" looks like by studying thousands of examples, then flag anything that deviates from that standard. Unlike rule-based systems that require explicit programming for every defect type, AI models adapt and improve as they see more data.

The workflow happens in four rapid steps. First, image acquisition occurs as products pass the camera station. The camera captures high-resolution images from one or multiple angles depending on inspection requirements.

Second, pre-processing enhances image quality. The system adjusts for lighting variations, removes background noise, and optimizes contrast to make defects more visible to the AI model.

Third, feature extraction identifies specific characteristics in the image. The AI model analyzes patterns, textures, dimensions, colors, and shapes, comparing them against learned standards for acceptable products.

Fourth, the real-time decision determines pass or fail. When the model detects a defect exceeding your predetermined threshold, it triggers an immediate action. The entire process—from image capture to decision—takes 50-200 milliseconds, fast enough for production lines running at almost any speed.

Implementation flexibility matters. Systems can deploy single-camera setups for simple inspections or multi-camera arrays for complex products requiring 360-degree inspection. You can start with one critical inspection point and expand as you prove ROI.

What Are The Primary Business Benefits Of Migrating To Automated Visual Inspection?

Computer vision delivers measurable improvements across quality, cost, and operational efficiency. These benefits justify the investment for manufacturers serious about competitive advantage.

Defect detection rates reach 98-99% with computer vision, up to 15% higher than manual inspection's 80-85%, catching micro-cracks, sub-millimeter deviations, color variations, and surface imperfections humans miss. In pharma blister pack inspection, systems detect seal defects and foreign particles missed by manual checks, preventing safety risks and regulatory issues.

Consistency represents another major advantage. The system applies identical standards to every single product, eliminating the variability inherent in human judgment. Part number 1 and part number 10,000 receive exactly the same scrutiny using exactly the same criteria.

Labor reallocation creates significant value beyond direct cost savings. Rather than replacing workers, smart manufacturers redeploy quality inspectors to higher-value activities like process analysis or managing multiple automated stations. By leveraging computer vision, companies can effectively bridge the gap between manual oversight and automated precision, ensuring their workforce is empowered by data rather than burdened by repetitive tasks.

One electronics manufacturer redeployed inspectors from manual PCB checks to process roles, cutting inspection time 80% and addressing defects via AI vision. Similar shifts identify tooling issues, with fixes yielding multi-fold scrap ROI (e.g., low-cost changes eliminating high annual waste).

Data-driven continuous improvement transforms how manufacturers approach quality. Computer vision systems generate detailed data on every inspected product. You see exactly which defect types occur most frequently, which stations produce the most rejects, which shifts have higher defect rates, and how defect patterns correlate with production speed, material batches, or environmental factors.

Vision systems reveal manual-inspection-blind insights, like foreign material spikes (e.g., plastic/stones post-weekend). A processor fixed cleaning issues causing contamination, eliminating 75% of events through data-driven root cause analysis.

Predictive maintenance becomes possible when you analyze defect trends. Gradually increasing rates of specific defects often signal deteriorating equipment before complete failure occurs. You can schedule maintenance proactively rather than reactively, reducing unplanned downtime.

Scrap reductions of 20-30% are standard post-implementation, via early detection saving material/labor. For 100,000-unit/month ops at 5% scrap dropping to 2%, this saves ∼3,000 units/month and boosts profitability.

Speed advantages matter for competitive positioning. Automated inspection never slows your line. You can increase production throughput without sacrificing quality, giving you capacity to accept more orders without capital investment in additional production equipment.

How Can I Integrate Computer Vision With My Existing MES Or ERP Systems?

Integration with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems transforms computer vision from a standalone quality tool into a component of your connected manufacturing ecosystem.

The closed-loop manufacturing approach connects inspection data directly to production control systems. When the vision system detects a defect, it doesn't just reject that part—it feeds information back to your MES about what defect occurred, when, and where. Your MES can automatically adjust process parameters, alert maintenance if patterns suggest equipment issues, or trigger quality holds on related batches.

Modern vision systems support standard industrial protocols like OPC UA, making integration straightforward. They can push inspection results, defect classifications, and operational data to your existing software infrastructure without requiring custom development.

Real-time dashboards give stakeholders visibility into quality metrics. Production managers see live defect rates by line and shift. Quality engineers drill into specific defect types and trends. Executives monitor overall equipment effectiveness (OEE) and quality costs. Everyone works from the same data, eliminating disagreements about quality performance.

Automated rejection mechanisms respond instantly to detected defects. The vision system can trigger rejection arms to remove defective parts from the line, pneumatic gates to divert them to scrap bins, or even stop production entirely if defect rates exceed critical thresholds. This automation eliminates the delay between detection and action, preventing defective products from contaminating good inventory.

IoT-enabled alerts notify the right people at the right time. When unusual defect patterns emerge, the system can send notifications to quality engineers via email, SMS, or mobile apps. Operators receive alerts at their workstations through visual and audible signals. Maintenance teams get notified when defects suggest equipment issues.

Traceability improves dramatically. Every product gets a digital record of its inspection results, time-stamped and linked to production parameters. If customers report issues, you can instantly query which products from that batch, shift, or timeframe might be affected. For regulated industries, this digital trail simplifies compliance and recall management.

The integration creates feedback loops that drive improvement. Production data flows into the vision system to correlate process parameters with defect rates. Vision data flows back to production systems to enable automatic corrections. This closed-loop approach optimizes quality continuously without manual intervention.

What Should I Look For When Choosing A Computer Vision Partner?

Selecting the right computer vision partner significantly impacts implementation success and long-term value realization. Focus on these critical factors during evaluation.

- Scalability determines whether the solution grows with your needs. Start with one inspection point, but ensure the platform can expand to dozens of cameras across multiple lines or facilities. The partner should offer modular hardware and software that scales without requiring complete system replacement.

Ask about multi-site deployments. Can you deploy the same models across facilities? How does the system handle centralized model management? As you prove ROI at one location, you'll want to replicate that success efficiently.

- Ease of model retraining: matters because defect patterns evolve. New products, material suppliers, or process changes require updating your vision models. Partners offering intuitive retraining tools let your team adapt models without data science expertise. Look for solutions where quality engineers can add new defect examples, retrain models, and deploy updates without vendor involvement.

Some vendors offer continuous learning capabilities where systems automatically improve as they see more examples. This reduces the maintenance burden and keeps inspection accuracy high as conditions change.

- Lighting-condition robustness: separates industrial-grade systems from consumer technologies. Factory environments have variable lighting, shadows, reflections, and ambient light changes throughout the day. Your system must perform consistently regardless of these variations.

Request demonstrations using your actual parts under your actual lighting conditions. Vendors confident in their technology will conduct proof-of-concept tests in your facility before you commit.

- Industry experience: indicates whether the partner understands manufacturing realities. Have they deployed systems in environments like yours? Can they share case studies from your industry? Partners with relevant experience anticipate challenges specific to your production environment and materials.

- Support and maintenance: capabilities ensure long-term success. What happens when you need help? Is support available during your production hours? How quickly do they respond to issues? What training do they provide for your team?

Look for partners offering comprehensive training programs covering system operation, basic troubleshooting, and model management. Your team should be able to handle routine maintenance and adjustments without constant vendor involvement.

- Total cost of ownership: includes more than initial purchase price. Evaluate licensing models, ongoing software fees, hardware refresh cycles, and training costs. Some vendors offer subscription-based pricing that reduces upfront investment and includes upgrades and support. Calculate ROI based on your specific defect rates, scrap costs, and labor expenses. A credible partner helps you build this business case rather than making generic promises.

Conclusion: The Shift From Inspection As A Cost Center To Vision As A Profit Driver

Computer vision fundamentally changes how manufacturers approach quality control. Traditional inspection focused on catching defects after they occurred—a necessary cost of doing business. Modern computer vision systems prevent defects, optimize processes, and generate insights that drive competitive advantage.

The technology has matured beyond early adoption phase. Hundreds of manufacturers across industries now rely on computer vision daily. Costs have decreased while capabilities have increased, making the business case compelling even for mid-sized manufacturers.

Success requires viewing computer vision not as a replacement for human judgment but as an augmentation that frees your team to focus on higher-value work. The goal isn't eliminating quality jobs—it's elevating them from repetitive checking to strategic problem-solving.

Manufacturers who implement computer vision gain immediate benefits in defect reduction and scrap savings. But the transformative value comes from the data these systems generate and how that data drives continuous improvement. You're not just automating inspection; you're building a foundation for intelligent, adaptive manufacturing that responds and improves automatically.

The question isn't whether to adopt computer vision—competitors already are. The question is how quickly you can implement it to maintain your quality advantage in an increasingly automated industry.

Ready to Modernize Your Quality Control?

Implementing automated visual inspection comes with unique challenges, from lighting optimization to data labelling. Our experts specialize in navigating these to ensure smooth, high ROI implementation.

FAQs

Frequently Asked Questions

About the Author

Mir Nasir

A lifelong technologist and social innovator, Mir Nasir builds companies at the intersection of technology, impact, and innovation. A seasoned founder behind ventures ranging from AI engineering firms to Pakistan’s largest managed services provider, his work consistently turns technology into meaningful opportunities for underserved communities and global enterprises alike.

Table of Contents

Newsletter Signup

Tomorrow's Tech & Leadership Insights in

Your Inbox

Discover New Ideas

NLP Advancements: Enhancing Customer Experiences in the Age of AI

Why Most Enterprise AI Projects Stall After the Pilot (And How to Fix It)

3+ Applications of Big Data in Healthcare (Real Examples)

Knowledge Hub