Driving Efficiency & Quality with AI-Powered Manufacturing

Discover our cutting-edge AI solutions that are transforming the manufacturing landscape. From predictive maintenance and intelligent automation to real-time quality assurance and supply chain optimization, we help manufacturers boost productivity, cut costs, and deliver top-notch product quality.

Addressing Manufacturing’s Biggest Challenges with AI-Powered Solutions

Manufacturing companies commonly face rising operational costs, labor shortages, supply chain disruptions, and the need for flawless quality at scale. Our AI solutions are purpose-built to help manufacturers overcome these hurdles, driving measurable improvements in efficiency, quality, and adaptability.

Predictive Maintenance

Unplanned equipment downtime disrupts production and inflates costs. AI-powered analytics detect anomalies and predict failures, enabling proactive maintenance and minimizing costly interruptions.

Quality Control

Manual inspections are slow and prone to human error. AI-driven vision systems inspect products in real time, catching defects with up to 98% accuracy and accelerating inspection speeds fivefold.

Intelligent Automation

Repetitive tasks drain skilled labor resources. Machine learning and robotics automate assembly, packaging, and logistics, boosting throughput and freeing workers for higher-value tasks.

Supply Chain Optimization

Volatile demand and logistics bottlenecks threaten delivery timelines. AI analyzes real-time data to optimize inventory, forecast demand, and streamline procurement for a resilient, agile supply chain.

Data-Driven Decision Making

Siloed data hinders strategic planning. AI consolidates and analyzes production, maintenance, and market data, providing actionable insights for continuous improvement.

Workforce Skills Gap and Labor Shortages

Shortage of skilled workers limits productivity and raises costs. AI-driven workforce analytics and training can accelerate upskilling to address talent shortages.

Addressing Manufacturing’s Biggest Challenges with AI-Powered Solutions

Manufacturing companies commonly face rising operational costs, labor shortages, supply chain disruptions, and the need for flawless quality at scale. Our AI solutions are purpose-built to help manufacturers overcome these hurdles, driving measurable improvements in efficiency, quality, and adaptability.

Predictive Maintenance

Unplanned equipment downtime disrupts production and inflates costs. AI-powered analytics detect anomalies and predict failures, enabling proactive maintenance and minimizing costly interruptions.

Quality Control

Manual inspections are slow and prone to human error. AI-driven vision systems inspect products in real time, catching defects with up to 98% accuracy and accelerating inspection speeds fivefold.

Intelligent Automation

Repetitive tasks drain skilled labor resources. Machine learning and robotics automate assembly, packaging, and logistics, boosting throughput and freeing workers for higher-value tasks.

Supply Chain Optimization

Volatile demand and logistics bottlenecks threaten delivery timelines. AI analyzes real-time data to optimize inventory, forecast demand, and streamline procurement for a resilient, agile supply chain.

Data-Driven Decision Making

Siloed data hinders strategic planning. AI consolidates and analyzes production, maintenance, and market data, providing actionable insights for continuous improvement.

Workforce Skills Gap and Labor Shortages

Shortage of skilled workers limits productivity and raises costs. AI-driven workforce analytics and training can accelerate upskilling to address talent shortages.

Addressing Manufacturing’s Biggest Challenges with AI-Powered Solutions

Manufacturing companies commonly face rising operational costs, labor shortages, supply chain disruptions, and the need for flawless quality at scale. Our AI solutions are purpose-built to help manufacturers overcome these hurdles, driving measurable improvements in efficiency, quality, and adaptability.

Predictive Maintenance

Unplanned equipment downtime disrupts production and inflates costs. AI-powered analytics detect anomalies and predict failures, enabling proactive maintenance and minimizing costly interruptions.

Quality Control

Manual inspections are slow and prone to human error. AI-driven vision systems inspect products in real time, catching defects with up to 98% accuracy and accelerating inspection speeds fivefold.

Intelligent Automation

Repetitive tasks drain skilled labor resources. Machine learning and robotics automate assembly, packaging, and logistics, boosting throughput and freeing workers for higher-value tasks.

Supply Chain Optimization

Volatile demand and logistics bottlenecks threaten delivery timelines. AI analyzes real-time data to optimize inventory, forecast demand, and streamline procurement for a resilient, agile supply chain.

Data-Driven Decision Making

Siloed data hinders strategic planning. AI consolidates and analyzes production, maintenance, and market data, providing actionable insights for continuous improvement.

Workforce Skills Gap and Labor Shortages

Shortage of skilled workers limits productivity and raises costs. AI-driven workforce analytics and training can accelerate upskilling to address talent shortages.

Delivering Real Impact in Manufacturing

Our AI solutions empower manufacturers to achieve operational excellence, superior product quality, and sustainable growth. With xLoop, you can achieve measurable results and sustainable growth in a rapidly evolving industry.

Client Retention Rate

Customer Satisfaction Rate

Successful Project

Transform Manufacturing with Our AI Solutions

Explore our suite of AI-powered solutions designed for the manufacturing sector to enhance efficiency, safety, and product quality.

Intelligent Quality Monitoring

Benefits of Integrating AI Solutions in Manufacturing

Unlock the full potential of your healthcare organization with AI-driven solutions.

Enhanced Product Quality

AI ensures consistent, high-precision inspections, reducing defects and recalls.

Streamlined Operations

Automate routine tasks, optimize workflows, and boost overall productivity.

Cost Savings

Reduce waste, energy consumption, and maintenance expenses through smarter resource management.

Greater Safety

AI-powered monitoring and predictive analytics enhance workplace safety by identifying hazards early.

Agility & Adaptability

Respond faster to market changes with real-time data insights and flexible production systems.

Enhanced Product Quality

AI ensures consistent, high-precision inspections, reducing defects and recalls.

Streamlined Operations

Automate routine tasks, optimize workflows, and boost overall productivity.

Cost Savings

Reduce waste, energy consumption, and maintenance expenses through smarter resource management.

Greater Safety

AI-powered monitoring and predictive analytics enhance workplace safety by identifying hazards early.

Agility & Adaptability

Respond faster to market changes with real-time data insights and flexible production systems.

Some Cool Stuff

We've Built

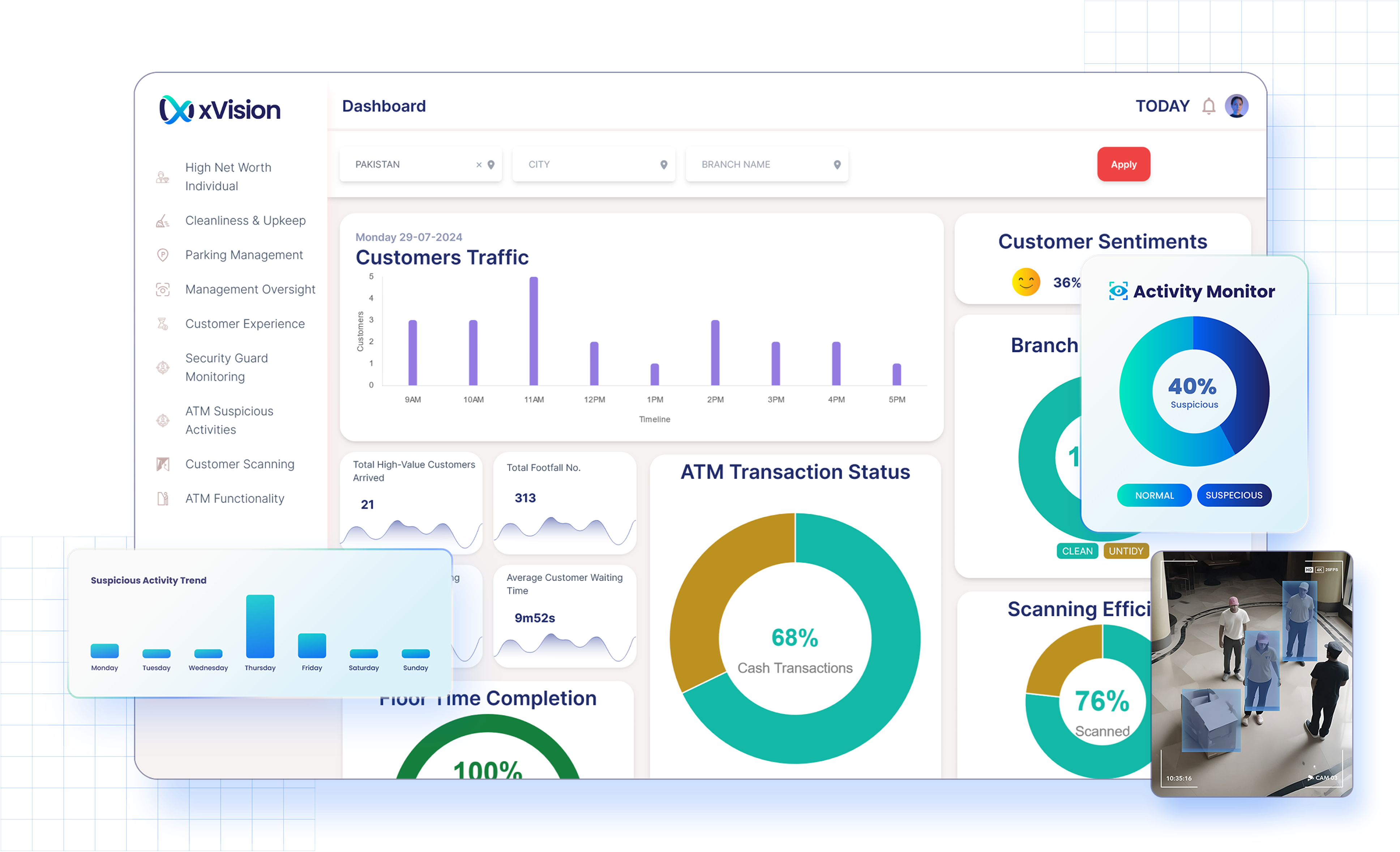

xVision: Where Visual Data Becomes Strategic Advantage

View Case Study

FAQs

Frequently Asked Questions

Discover New Ideas

NLP Advancements: Enhancing Customer Experiences in the Age of AI

Why Most Enterprise AI Projects Stall After the Pilot (And How to Fix It)

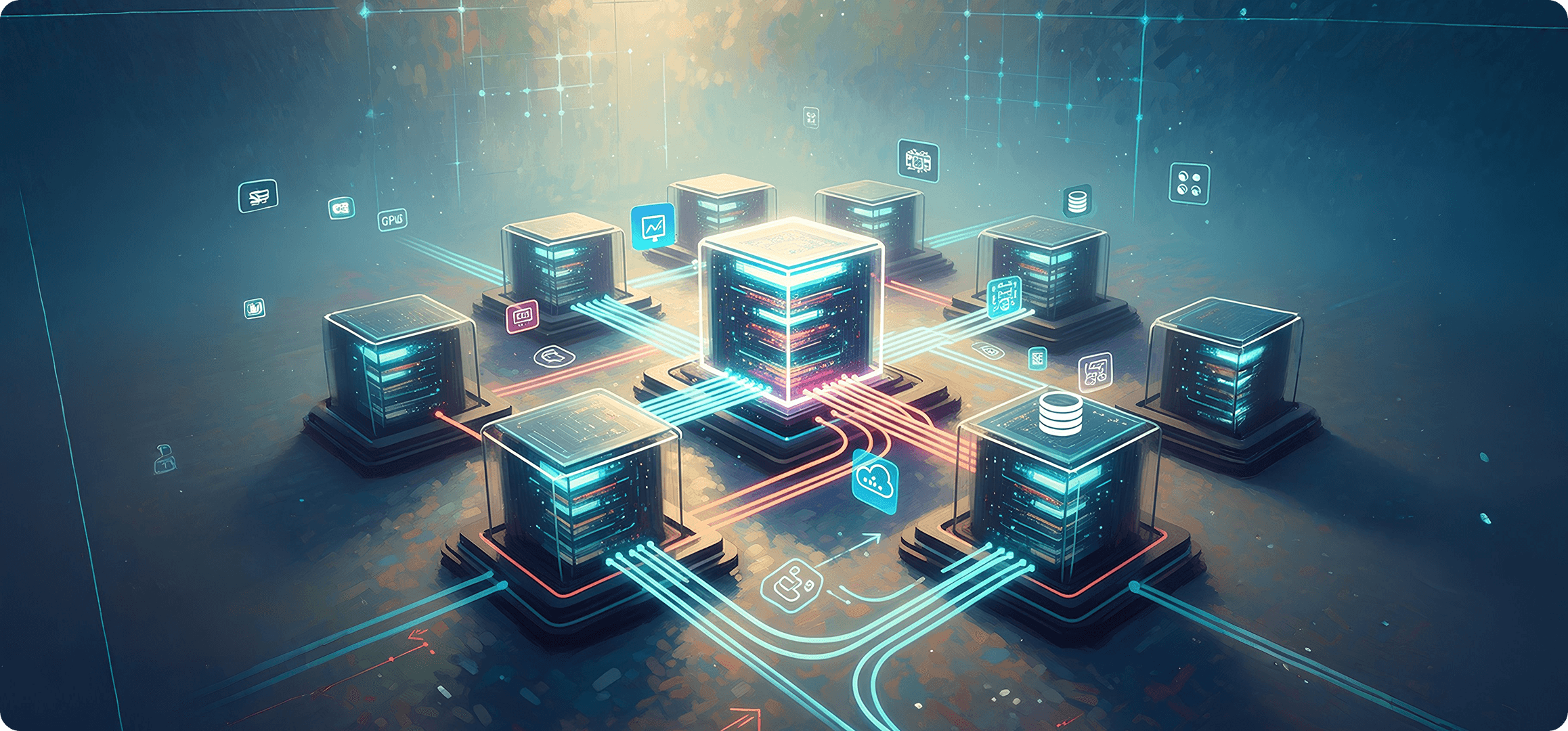

Building Scalable AI Infrastructure: Lessons from Real-World Implementations